Main features

l Domestic exclusive use of digital gas flow meter control, automatic switching gas

l Unique dual temperature probe design for higher temperature accuracy (TH-9002)

l 7-inch microcomputer touch screen control, full automation, easy operation

l Experimental process, no need for supervision

l End of experiment, beeping reminder

l The diameter of the rubber discharge port can be up to 12mm, so there is no need to worry about clogging.

l Heating zone of 220 mm for simultaneous measurement of three samples

l Quartz tubes can be removed to accelerate cooling and reduce waiting time

l The instrument can communicate with computer via USB to realize remote monitoring.

Technical Parameters

temperature range | RT~1100℃ | temperature fluctuation | ±0.2°C |

heating rate | 0.1~40℃/min | Temperature resolution | 0.01°C |

gas pressure | 0.2MPa | Temperature control method | Full automatic control |

gas flow | 0~300mL/min or 0~2000mL/min | Atmosphere control | Gas Mass Flow Meters |

Display mode | 24bit color, 7" touch screen | heating zone | Length 220mm |

quartz tube | Length 440mm, Inner Diameter 32mm | quartz boat | Length 50mm or 75mm |

Overall dimensions (w*d*h) | 42*37*40cm | Net weight | 25KG |

Package size (w*d*h) | Wooden case 61*50*52 | gross weight | 41KG |

Experimental procedure

1. Pressure reducing valve connects 2. Put about 1 gram of sample into

nitrogen and oxygen cylinders and opens. the center of the quartz tube

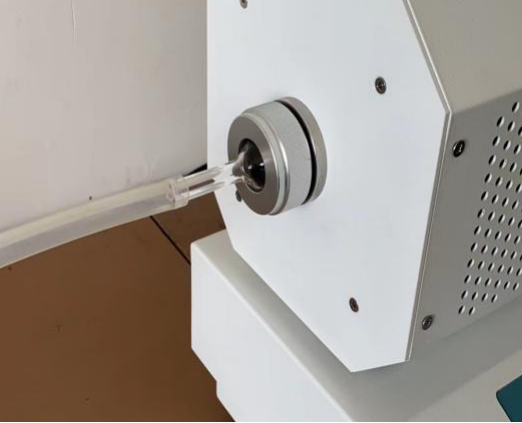

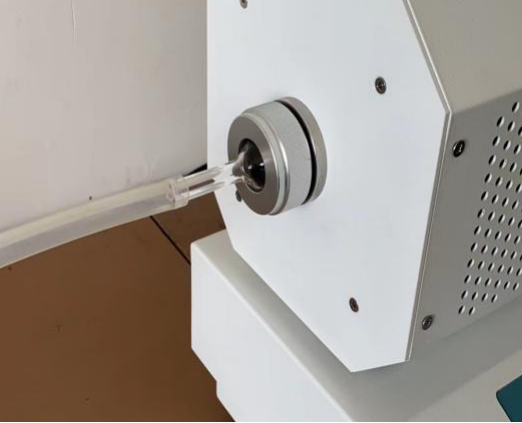

3. Plug the rubber plug with the air 4. Stone the quartz tube into the furnace

tube into the quartz tube. chamber and tighten the flange.

5. Connect the exhaust hose with the quartz tube. 6. End of pyrolysis or calcination, wait for the temperature to drop to about 200 degrees, take out the Quartz tubes are placed on a pallet to cool.

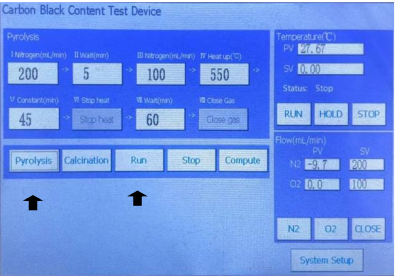

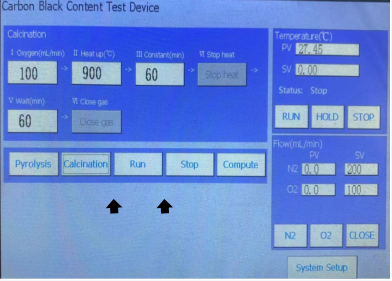

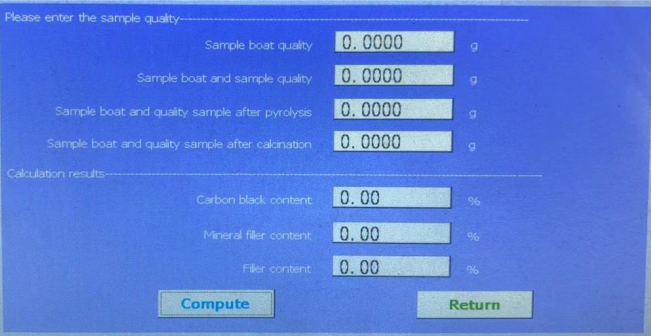

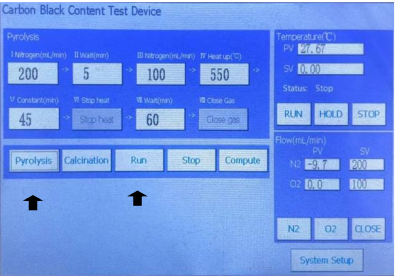

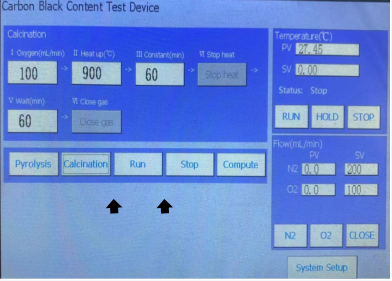

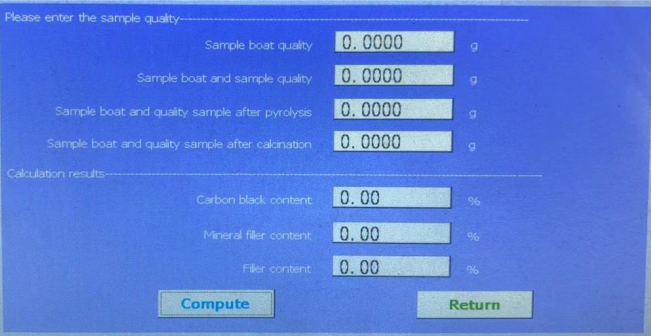

Flowchart of software operation (plastic pipes as an example)

The whole process of heating, waiting, ventilation and air exchange is automatically controlled without human intervention.

1. Pyrolysis 2. Calcination

3. Calculations

Carbon Black Content Tester Accessories

serial number | Name | quantities |

1 | Carbon Black Content Tester Heating Furnace and Main Chassis | 1 unit |

2 | Carbon Black Content Tester Instruction | 1 copy |

3 | power cable (of an appliance etc) | 1 root |

4 | prototype boat | 5 pieces |

5 | Glass tube fuse (10A) | 4 |

6 | Ventilation plastic tube (blue) | 3 meters |

7 | Ventilation plastic tube (orange) | 3 meters |

8 | certificate of conformity | 1 copy |

9 | Pressure Reducing Valve Fitting | 2 pieces |

10 | air vent | 4 |

11 | Sample Hooks | 1 handle |

12 | Sample boat catching spoon | 1 handle |

13 | φ38 quartz tube | 1 stick |

14 | exhaust hose | 1.5 meters |

15 | stylus | 1 stick |

16 | crucible tongs | 1 handle |

Download

INQUIRY

INQUIRY