Products Detail Technical Parameter Feature And Application Fields Of Use Details Download

1. Product introduction

The Explosion-proof cryogenic coolant circulator is a kind of water cooling equipment, which can provide constant temperature, constant current and constant pressure cooling water equipment. Its working principle is to first inject a certain amount of water into the water tank in the machine, cool the water through the refrigeration system, and then send the low-temperature chilled water to the equipment that needs to be cooled by the water pump. The chilled water takes away the heat of the equipment that needs to be cooled and the temperature rises. The high is sealed and returned to the water tank to achieve the cooling effect. The cooling water temperature can be automatically adjusted according to requirements, and long-term use can save water. Therefore, the chiller is also a standard energy saving and environmental protection equipment. The operation of the chiller system is through three interrelated systems: the refrigerant circulation system, the water circulation system, and the electrical automatic control system.

2. Product parameter

Model | YK-600 |

Temperature range | 5~35℃ |

Temperature control accuracy | ±0.1℃ |

Different water temperature | 5℃ | 10℃ | 15℃ | 20℃ | 25℃ | 30℃ | 35℃ |

Cooling capacity | 420W | 510W | 550W | 605W | 620W | 670W | 750W |

Water tank volume | 5L |

Heating power | Bypass |

Cycle pressure | 0~0.8bar |

Circulating flow rate | 0~15L/min |

Interface size | 1/2″NPT |

Instrument weight | 39kg |

Whole machine power consumption | 290W |

Dimensions | 290x550x540mm |

Standard adapter | Pagoda head with 8mm and 10mm outer diameter |

Power requirements | 220V/50HZ/10A |

RS485 communication interface | Optional (additional charge) |

Water circuit on-off signal output interface | Optional (additional charge) |

3. Product features and application

Professionally designed dynamic temperature control system with high temperature control accuracy and small temperature fluctuations; simple and convenient man-machine interface, automatic memory of control parameters; various refrigeration power and circulating pump pressure, which can meet the cooling and constant temperature of various instruments; refrigeration The key components of the system adopt imported famous brand products, which are stable and reliable; a variety of circulating pumps, optional ultra-quiet, high pressure or large flow, equipped with stainless steel pressure indicator; standard stainless steel interface, can be equipped with various specifications of joints and hoses, external Closed loop; optional power failure recovery function, optional flow alarm.

4. Refrigerant circulation system

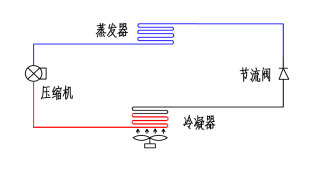

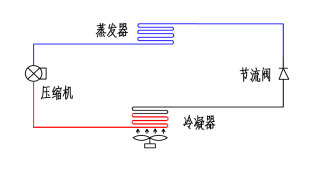

The liquid refrigerant in the evaporator absorbs the heat in the water and starts to evaporate. Eventually, a certain temperature difference is formed between the refrigerant and the water. The liquid refrigerant is also completely evaporated and becomes gaseous, then sucked by the compressor and compressed (pressure and temperature increase) , The gaseous refrigerant absorbs heat through the condenser (air-cooled/water-cooled), condenses into a liquid, throttling through the thermal expansion valve (or capillary), and turns into a low-temperature and low-pressure refrigerant to enter the evaporator, completing the refrigerant cycle process.

5. Schematic diagram

Schematic diagram of basic components

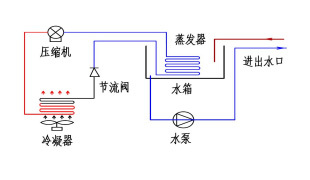

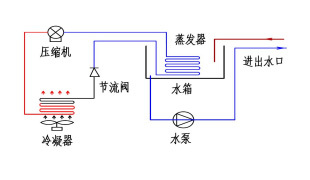

Water circulatory system

The water circulation system is a water pump that pumps water from the water tank to the user's equipment that needs to be cooled. The chilled water takes away the heat and the temperature rises, and then returns to the chilled water tank. The working principle diagram of the chiller is as follows:

Download

keyword search:Explosion-proof cryogenic coolant circulator

INQUIRY

INQUIRY