Main feature

l Simple operation, no testing experience, only a small amount of training.

l The software is suitable for computer screens with different resolutions.

l Double temperature probes ensure high accuracy and repeatability.

l During the experiment, there is no need for personnel supervision.

l Digital gas mass flowmeter automatically switches two gas flows.

l Software can be upgraded online for free.

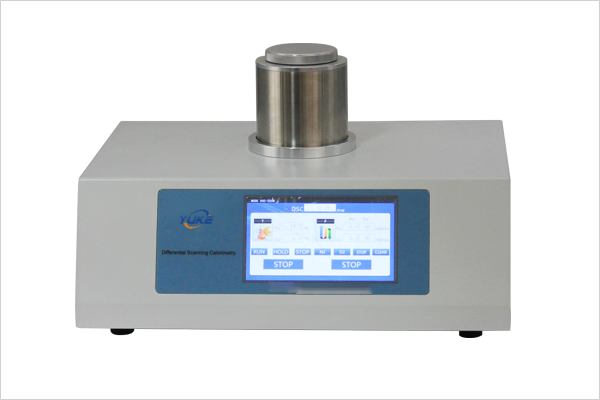

l Seven-inch LCD display, the map and curve are clear at a glance.

l Liquid nitrogen refrigeration, the lowest temperature can reach -150℃

Technical parameter

DSC range | 0~±200mW | Temperature range DSC-500L | -150~500℃ |

heating rate | 0.1~30℃/min |

|

|

Refrigeration | Liquid nitrogen refrigeration | temperature resolution | 0.01℃ |

Temperature accuracy | ±0.1℃ | Temperature repeatability | ±0.1℃ |

DSC accuracy | ±2% | DSC resolution | 0.001mW |

DSC resolution | 0.001mW | Temperature control mode | Full automatic control |

Curve scanning | Heating and cooling scanning | Atmosphere control | Digital gas mass flowmeter |

display mode | 24bit color, 7-inch touch screen | working power supply | AC220V 50Hz/60Hz |

Size (w*d*h) | 46*35*38cm | Net weight | 23KG |

Packing size (w*d*h) | 58*45*40 | Gross weight | 26KG |

Computer configuration requirements | Minimum hardware configuration l Celeron dual core l 2GB system memory l Resolution 1366*768 pixels or higher. l Hard disk 500G | Minimum software configuration l Win10/11 l Adobe PDF reader |

Application example

Measure physical and chemical changes related to heat, such as glass transition temperature, melting point, melting temperature, crystallization and crystallization heat, phase transition reaction heat, thermal stability of products, curing/crosslinking, oxidation induction period, reaction kinetics, specific heat, etc. Note: the thermal stability test during oxidation induction period is applicable to G B/T 1 7 3 9 1-1 9 9 8.

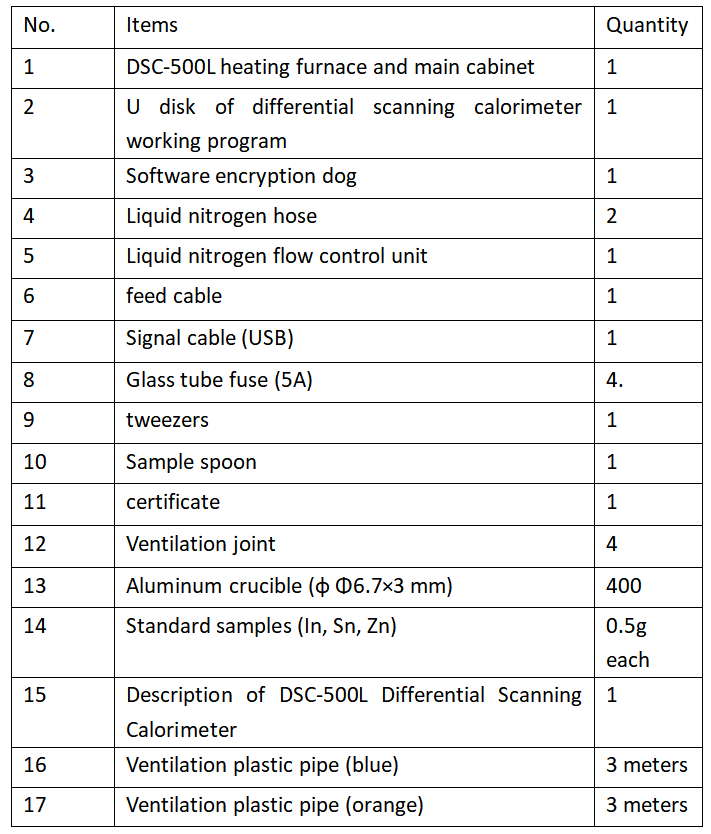

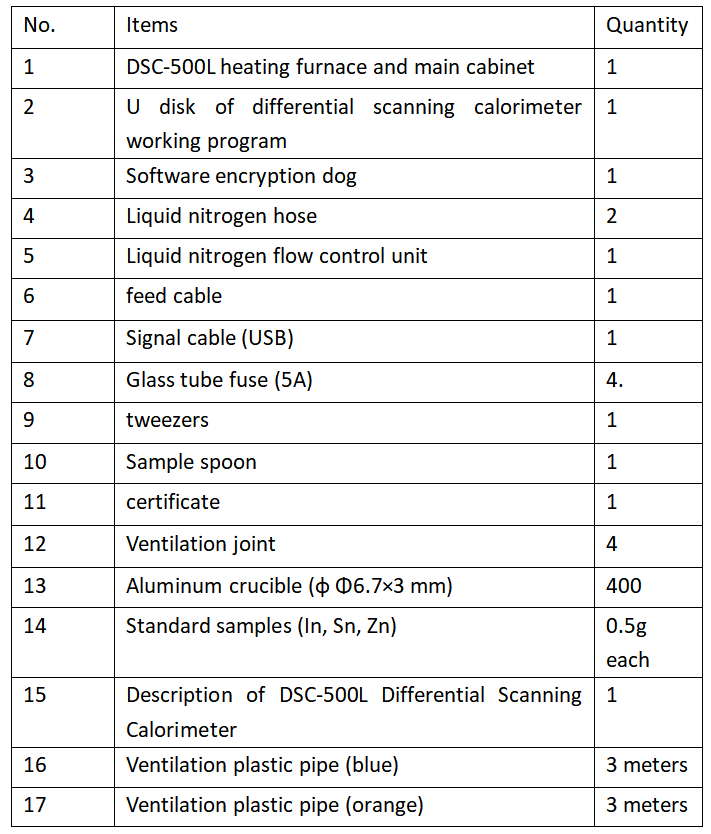

List of accessories of DSC-500L series

Instrument principle

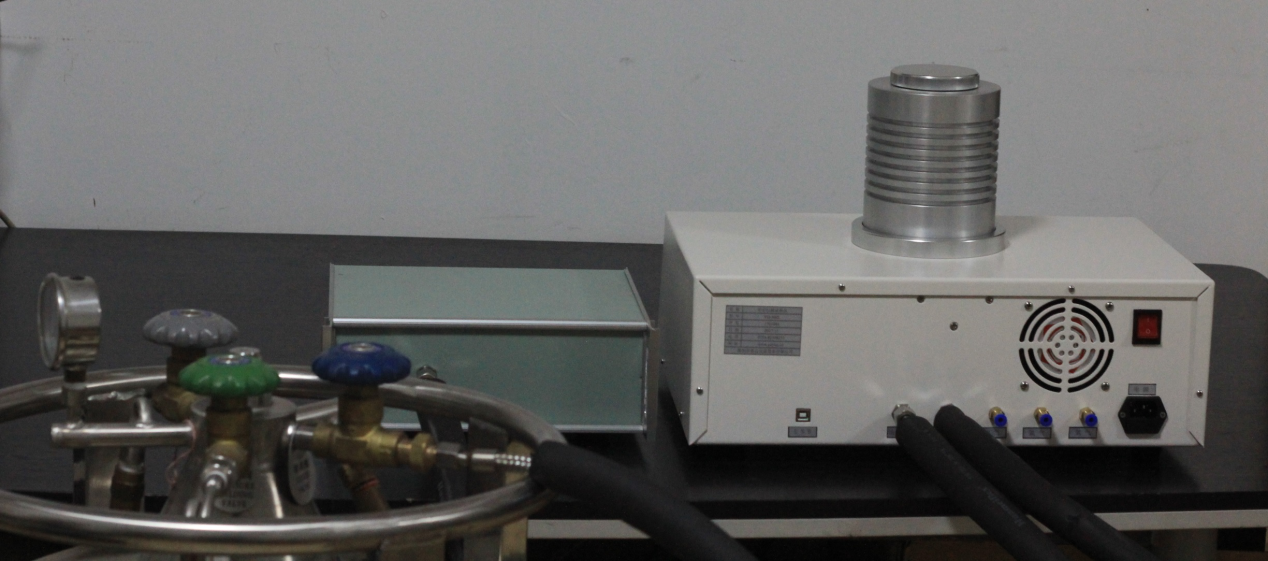

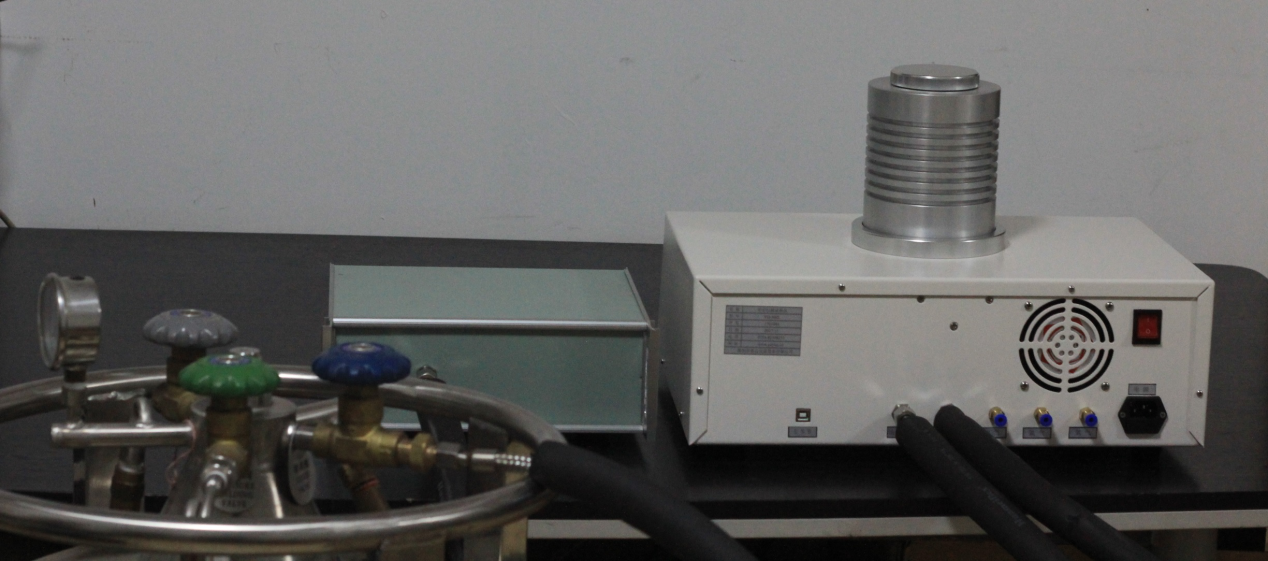

Differential scanning calorimetry (DSC) is a technique to measure the power difference between substance and reference under the control of programmed temperature. Differential scanning calorimeter is mainly composed of heating furnace, host, microvolt amplifier, A/D converter, data acquisition system, gas flow control system, computer, printer and other components, supplemented by the switching of two channels of atmosphere, and the measurement results are processed by computer data processing system.

Download

keyword search:Differential scanning calorimeter

INQUIRY

INQUIRY