Main Features:

l Simple to operate, no testing experience required, only a small amount of training required

l Software for computer screens of all resolutions

l Dual temperature probes to ensure high accuracy and repeatability

l Experimental process, no need for supervision

l Digital gas mass flow meter automatically switches between two gas flows

l Software can be upgraded online for free

l Seven-inch large screen LCD display, graphs and curves at a glance

Technical parameters:

DSC range | 0 to ±200mW | Temperature range | Room temperature~500℃ |

Heating rate | 0.1~50℃/min | Temperature resolution | 0.01°C |

Temperature Accuracy | ±0.1°C | Temperature Repeatability | ±0.1°C |

DSC Accuracy | ±2% | DSC Resolution | 0.001mW |

DSC resolution | 0.001mW | Temperature control method | Full automatic control |

curve scan | temperature rise scan | Atmosphere control | Gas Mass Flow Meters |

Display mode | 24bit color, 7" touch screen | Operating power | AC220V 50Hz/60Hz |

Dimensions (w*d*h) | 46*35*27cm | Net weight | 14.5KG |

Package size (w*d*h) | 58*45*40 | gross weight | 18KG |

transducers | Domestic high sensitivity |

|

|

Computer Requirements | Minimum hardware configuration l Celeron Duo l 2GB system memory l Resolution 1366*768 pixels or higher l Hard disk 500G | Minimum software configuration l Win10/Win11 or higher l Adobe PDF Reader |

Examples of applications

Measurement of physical and chemical changes related to heat, such as glass transition temperature, melting point, melting temperature, crystallization and heat of crystallization, solidification, heat absorption and exothermic peaks, heat of reaction of phase transition, thermal stability of the product, curing/cross-linking, oxidation-induced period, reaction kinetics, specific heat and so on. Note: The thermal stability experiment of oxidation induction period applies to the national standard GB/T17391-1998, GB/T19466.6-2009, GB/T19812.1-2017, SH/T1750-2005 and so on.

Instrument Principle

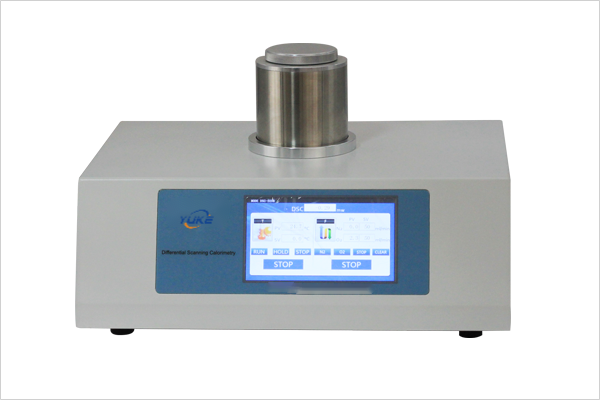

Differential scanning calorimetry (Differential scanning calorimetry) is a technique to measure the power difference between the substance and the reference under the program temperature control with the change of temperature.DSC-500 series differential scanning calorimeters are mainly composed of heating furnace, main unit, micro-volt amplifier, A/D converter, data acquisition system, gas flow control system, computer, printer and other components, and supplemented by two-way atmosphere switching, the measurement results are processed by the computer data processing system.

DSC-500 Series Accessories List

No. | Name | Quantities |

1 | DSC-500B heating furnace and main chassis | 1 |

2 | DSC-500 Differential Scanning Calorimeter Working Program U disk | 1 |

3 | power cable (of an appliance etc) | 1 |

4 | signal cable | 1 |

5 | Glass tube fuse (3A) | 4 |

6 | tweezers | 1 |

7 | spoon | 1 |

8 | certificate of conformity | 1 |

9 | Pressure Reducing Valve Fitting | 2 |

10 | air vent | 4 |

11 | Aluminum crucible (Φ6.7×3mm) | 400 |

12 | Standard samples (In, Sn, Zn) | 0.5g each |

13 | DSC-500 Differential Scanning Calorimeter Specifications | 1 |

14 | Ventilation plastic tube (blue) | 3 meters |

15 | Ventilation plastic tube (orange) | 3 meters |

16 | software dongle | 1 |

Download

keyword search:DSC Differential Scanning Calorimeter

INQUIRY

INQUIRY