I. Working Principle

Use the heat energy provided by the flame itself to excite some atoms in the alkaline earth metal, so that these atoms absorb energy and then jump to the previous energy level. When it falls back to the normal energy level, it will release energy. This released energy has spectral characteristics, that is, within a certain wavelength range. For example, when salt is placed in the fire, the flame is yellow, because the spectrum of energy released by sodium atoms when the flame falls back to the normal energy level is yellow. People often call this the flame color reaction. Different alkali metals or alkaline earth metals have different colors in the flame, and with different filters, qualitative tests can be performed. The intensity of the flame color is proportional to the solubility of the atoms contained in the solution, which forms the basis for quantitative testing. This method is usually called flame photometry, and this type of instrument is usually called a flame photometer.

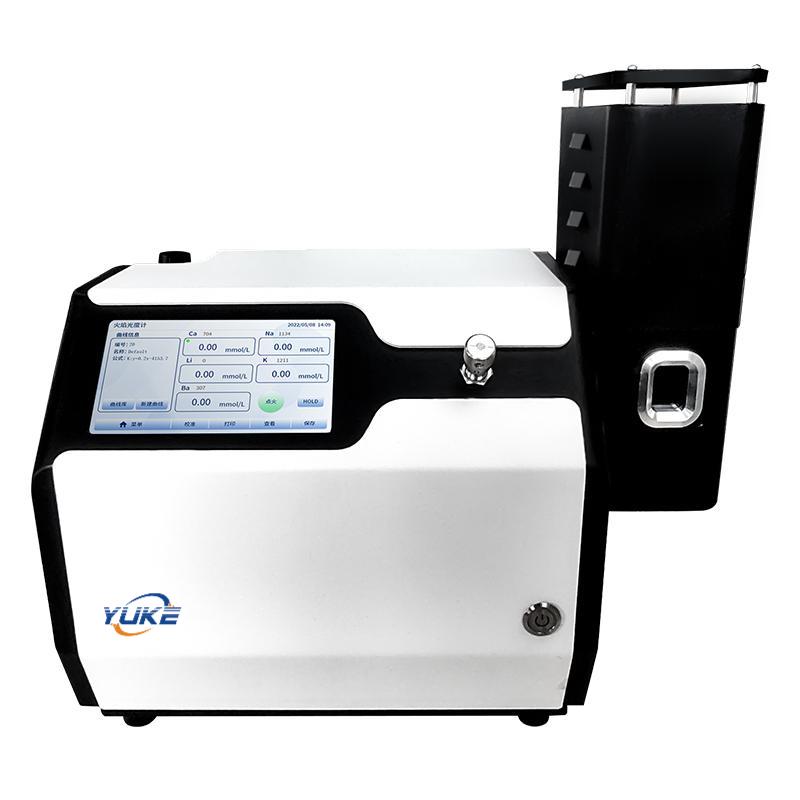

II. Features of FP6432 flame photometer

1. It has cloud interconnection function;

2. It has automatic calculation function of correlation coefficient;

3. It has U disk data export and USB communication port;

4. The host adopts 7-inch color capacitive touch LCD screen;

5. It has direct reading function of potassium, sodium, lithium, calcium and barium element concentration;

6. It has the advantages of small size, easy operation and stable and reliable;

7. Flame failure protection device and gas leakage alarm, safe and reliable;

III. FP6432 flame photometer instrument parameters

1. Instrument model: FP6432

2. Test items: K、Na、Li or (K、Na、Ca) or ( K、Na、Ba )

3. Curve calibration: broken line method, straight line method

4. Stability: The relative maximum change of the instrument indication within 15s is ≤3%

5. Power supply voltage: AC220±22V50HZ±1HZ

6. Rated power: 30W

7. Printer: optional

8. Filter transmittance characteristics:

(1) Potassium, lithium, calcium, barium: peak wave The absolute value of the length error is ≤7nm; Sodium: the absolute value of the peak wavelength error is ≤5nm;

(2) Potassium, sodium, lithium, calcium, barium: half width ≤15nm; Potassium, sodium, lithium, calcium, barium: background transmittance ≤0.5%;

IV. Normal working conditions

1. Ambient temperature (10°~35°)C

2. Relative humidity ≤85%

3. The product should be placed horizontally on a vibration-free workbench to avoid direct exposure to strong light, strong electric and magnetic field interference, strong airflow, and vibration that affects use;

4. There should be no flammable, explosive, or corrosive gases at the product use site, and fire extinguishing equipment should be available;

5. Maintenance:

(1). After the air compressor has worked for about 100 hours, the power supply should be cut off and the sealing plug at the bottom of the air tank should be unscrewed to drain the water in the air tank. The time of humidity in the environment should be shortened appropriately.

(2). When the air filter is under pressure, push the pin at the bottom of the filter upwards, and the accumulated water will be discharged. It is best to put a rag underneath and put the water on the rag. After draining, release it by hand to reset it.

(3). After each test, it should be cleaned with distilled water for about 5 minutes. That is, the sampling capillary is placed in distilled water and burned for 5 minutes as in normal operation, and the atomization chamber and the combustion head are cleaned in a cycle.

V. Application areas:

1. Testing of building materials such as cement, glass, ceramics, and refractory materials;

2. Testing of fertilizers and soil;

3. Testing of mining, petroleum, metallurgy, and chemical products;

4. Testing of pharmaceuticals, beverages, and other foods;

5. Testing of urban domestic waste;

6. Testing of various experiments in scientific research, health, and teaching.

Download

INQUIRY

INQUIRY