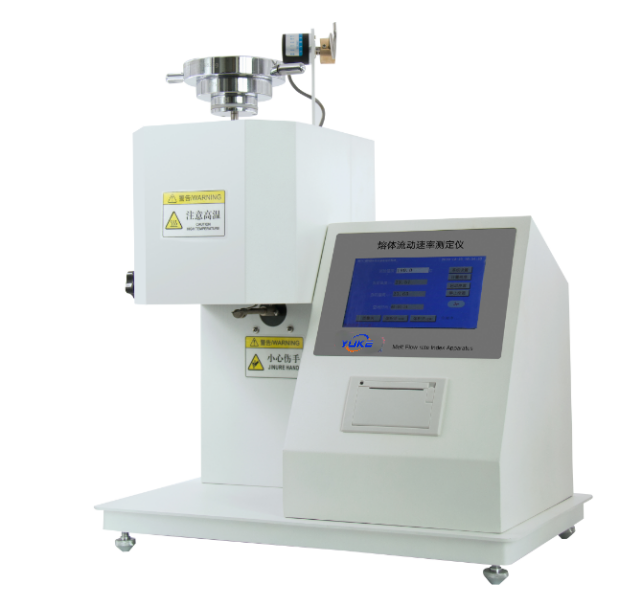

Brief Introduction

YK-450 series melt flow rate meter is mainly used for the analysis and research of melt flow rate of thermoplastics under certain conditions. Melt flow rate of thermoplastics (melt index) refers to the plastic at a certain temperature and load, melt every 10 minutes through the standard die mass, expressed by MFR (MI) value, which can distinguish thermoplastics in the molten state of the viscous flow characteristics. The test is of great significance to the quality assurance of raw materials and products of thermoplastics and chemical fiber. Shanghai Yuke YK-450A YK-450T Melt Index Tester is fully in line with ASTM D 1238 standard, and improved and upgraded to facilitate the test of high flow instant fat meter, especially suitable for the melt-blown material PP (polypropylene), polyethylene and other materials test.

Meet the quality standards

ISO 1133-2011, ASTM D1238-13, GB/T 3682-2018, JJG878-1994 (2005), JB/T5456-2005

The main features

1. The equipment adopts PID intelligent temperature control with high temperature control accuracy, which can ensure that the temperature at the upper 10 mm of the inner die of the cylinder is within ±0.5℃.

2. After packing, can quickly restore the constant temperature state

3. Nitriding processing of key parts, high strength, hardness, small deformation characteristics and ensure the accuracy and stability of the measured data.

4. The heating speed is fast, the instrument heater adopts special spring heating ring of hot runner, and its main material is imported nickel chromium wire alloy. Compared with the traditional heater, the dry burning ability is stronger, the power is higher, the heating uniformity is better, the service life is long, and the instrument can work for a long time at high temperature 450℃.

5. The instrument is heated by voltage regulating module, which can adjust the voltage and power in a full range. Compared with the traditional solid-state relay on-off control, the heating is more stable and rapid, so that the constant temperature can be quickly restored after packing.

6. The instrument adopts custom-made armored platinum resistance temperature sensor, the accuracy is the highest grade A, the accuracy is within 0.1℃, compared with the traditional sensor, has the characteristics of impact resistance, corrosion resistance, vibration resistance and can be bending at will, the service life is longer, can ensure the instrument in 450℃ the highest temperature environment for A long time.

Technical parameters

Model | YK-450A |

advantage | Can measure products with fast flow rate, with membrane plug |

Measurement methods | Mass method Volume method |

Display method | LCD color touchscreen |

Timekeeping accuracy | 0.01S |

Cutting method | Manual / Auto |

Measuring range | (0.1-2000)g/10min , (YK-450T range (0.1-3000)g/10min ) |

Recovery Time | ≤2min |

Result output | Mini printer |

power supply | 220V,50HZ |

Extrusion part |

Inner diameter of discharge port (die) | φ 2.095±0.005mm |

Length of outlet (die) | 8.000±0.025mm |

Inner diameter of barrel | charging | φ 9.550±0.007mm |

Length of charging barrel | 152mm |

Piston rod head diameter | φ 9.474±0.007mm |

Piston rod head length | 6.350±0.100mm |

Piston displacement indication error | ±0.01mm |

Load part: the standard test force is eight grades, the relative error of the test load is ≤0.5%, and the mirror plating standard is adopted |

Level 1 | 0.325kg=(piston rod+weight tray+heat insulation sleeve+1 weight body) |

level 2 | 1.200 kg=(0.325+0.875 weight No. 2) |

Level 3: | 2.160 kg=(0.325+No. 3 1.835 weight) |

level 4: | 3.800 kg=(0.325+No. 4 3.475 weight) |

Level 5: | 5.000 kg=(0.325+No. 5 4.675 weight) |

Level 6: | 10.000 kg = (0.325 + No. 5 4.675 weight + No. 6 5.000 weight) |

Level 7: | 12.500 kg = (0.325 + No. 5 4.675 weight + No. 6 5.000 + No. 7 2.500 weight) |

Level 8: | 21.600 kg=(0.325+No.2 0.875+No.3 1.835+No.4 3.475+No.5 4.675+No.6 5.000+No.7 2.500+No.8 2.915 weights) |

Barrel temperature |

Barrel temperature range | The temperature control point can be set arbitrarily within the range of 50.0℃~450.0℃ |

Adopt intelligent PID adjustment | Reach temperature control point and keep constant temperature in a short time |

Constant temperature accuracy | ±0.2℃ |

Temperature control gradient (℃): | ≤±0.5℃ (10mm above the die) |

Temperature resolution | 0.01℃ |

Download

keyword search:Melt index meter

INQUIRY

INQUIRY