Host technical parameters:

The host adopts professional industrial magnetron emission microwave control technology, double frequency conversion and double magnetron, adjusts the microwave output power in real time according to the temperature and pressure feedback, realizes continuous non pulse microwave output, ensures more uniform microwave magnetic field in the cavity, and ensures the consistency of digestion of experimental samples.

2. The instrument adopts professional PID control theory, high-performance microprocessor and new sensing technology to realize multiple automatic protection functions and multiple safety protection measures.Realize automatic detection, fault alarm, ensure the safety of the experiment.

3. High resolution liquid crystal display can display the temperature and pressure of the closed reaction tank in real time, and can display the operation curve of temperature and pressure in real time.

*4. The indicator light on the touch screen panel will prompt the safety function of the furnace door in time, so as to know the reliability of the furnace door closing in time, ensure the safe operation of the instrument, and ensure the operation status of the high-definition 4K display.

*5. The indicator light on the panel will prompt whether the key function is normal.The key operation adopts the most reliable non-contact sensing operation mode, which is resistant to acid gas corrosion in laboratory, with high sensitivity and fast reaction.It can avoid the failure caused by poor contact or poor reliability of the film circuit of the traditional mechanical keys due to frequent touch.

*6. The panel indicator lights prompt the operation function of the instrument and the operation status of the microwave signal in time to know whether the instrument is running normally.

*7. The indicator light on the panel monitors the operation status of the rotary table. If the rotary table is abnormal, the alarm will be given immediately and the operation of the instrument will be terminated. The microwave emission and rotation of the rotary table will be stopped, so as to avoid the phenomenon of uneven heating of the tank due to the continuous input of microwave when the rotary table is not rotating.

*8. 360 ° unidirectional rotation makes the turntable rotate more freely without pause in the process of rotation, ensures the uniformity of microwave heating, reduces the impact on the turntable motor, and extends the service life of the instrument.

*9. 45L large capacity industrial microwave oven cavity, inside and outside the overall spray 8 layers of Teflon treatment, corrosion resistance, high temperature resistance, prevent strong acid corrosion.

10. Six layer steel structure bulletproof glass explosion-proof furnace door, self ejecting buffer structure design, double locking self-test, panel light indication.

*11. 360 degree unidirectional continuous rotation microwave stirring technology: the temperature and pressure measurement and control device and digestion tank rotate synchronously with the turntable in the same direction. The uni turn technology does not need to rotate 360 degrees back and forth, and there is no pause in the rotation process. The digestion tank is heated under the condition of uniform distribution of microwave field.

12. The furnace cavity adopts top exhaust mode and is equipped with high-power exhaust cooling system. The exhaust flow is more than or equal to 5.8 m3 / min to realize rapid cooling and improve safety and work efficiency.

13. Servicing mass: 77kg.

14. Overall dimension: 770 mm × 620 mm × 840 mm

Control system parameters:

1. The temperature measurement range is - 40 ~ 500 ℃, the control accuracy is ± 0.1 ℃, and the display accuracy is ± 1 ℃.It is composed of stainless steel sleeve, which has the advantages of small volume, impact resistance, long service life, and can correctly and quickly reflect the actual temperature of the end face to be measured.At the same time, the plug-in design structure is adopted, and the sensor must be pulled out when taking out the digestion tank from the furnace cavity, so as to avoid the instrument damage caused by the user starting the program without setting out the sample.

*2. High precision piezoelectric crystal pressure control system, real-time detection, control and display the pressure and curve in the reaction tank, non-contact pressure sensor, to avoid cross contamination caused by direct contact with the sample; Pressure control range: 0-10mpa, control accuracy: 0.01Mpa.

Technical parameters of digestion tank:

*1. The outer tank is made of imported high-strength aerospace composite fiber material, with a pressure resistance of 85mpa and a temperature resistance of 600 ℃. Its physical properties and corrosion resistance are better than those of traditional modified PEEK material

2. The inner tank adopts imported modified polytetrafluoroethylene (TFM) and high-strength frame type closed ultra-high pressure reaction tank: the maximum bearing temperature is more than or equal to 300 ℃.

*3. The safety design of explosion-proof membrane automatic pressure relief and bow spring module pressure relief ensures the safe operation of the instrument.

4. Full tank pressure monitoring system: bow spring design, overpressure automatic relief, quantitative value adjustable

Model Detail As below :

Model | MWD6 | MWD8 | MWD10 | MWD12 | MWD14 | MWD15 | MWD20 | MWD24 | MWD40 |

Power | AC220V / 50Hz |

Microwave frequency | 2450(MHz) |

Microwave power | 1000 (W) | 1200 (W) | 1500 (W) | 1500 (W) | 1800 (W) | 1800 (W) | 2000 (W) | 2400 (W) | 3200 (W) |

Oven chamber | 45(L) | 45(L) | 50(L) | 50(L) | 80(L) | 80(L) | 80(L) | 90(L) | 120(L) |

Protective spraying | PFA |

Heating mode | PID frequency conversion technology |

Warming slope | 1-50 ℃/min |

Cooling time | ≤25 min |

Microwave leakage | ≤0.3mW/cm2 |

Temperature control range | 0-300 ℃ |

Temperature accuracy | 0.1 ℃ |

Control pressure range | 0-6 Mpa |

Pressure control accuracy | 0.01 Mpa |

Outer tank material | PEEK |

Inner tank material | TFM1700 |

Maximum temperature resistance | 300 ℃ |

Operating temperature | 250 ℃ |

Instrument configuration:

| Items | Quantity | Remarks |

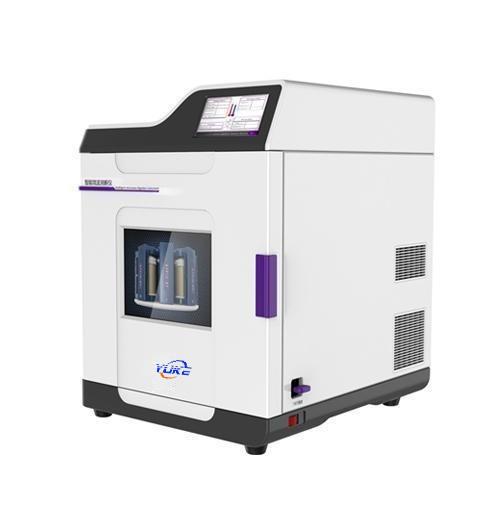

1 | Host of microwave digestion system | 1 | Integrated display and operating system |

2 | High pressure digestion reaction tank rack | 1 | Pressure sensor with piezoelectric crystal |

3 | High pressure digestion reaction inner tank | According to the model |

4 | High pressure digestion reaction outer tank | According to the model |

5 | High precision platinum resistance temperature sensor | 1 |

|

6 | Anticorrosive telescopic ventilation pipe for exhaust cooling system | 1 | Automatic exhaust fan cooling system |

7 | High strength HP sample holder | 3 |

|

8 | Instructions for microwave digestion | 1 |

|

9 | Warranty card / certificate | 1 |

|

10 | Operation toolbox | ① Yingmai two way ratchet wrench | 1 |

|

|

| ② Lock wrench for air release valve | 1 |

|

|

| ③ Sealed cup lid expander | 1 |

|

|

| ④ Explosion proof membrane | 500 |

|

|

| ⑤ Deli stainless steel tweezers | 1 |

|

|

| ⑥ Spare fuse 1 | 1 | 3.5A |

|

| ⑦ Spare fuse 2 | 1 | 10A |

|

| ⑧ Toolbox | 1 |

|

Download

INQUIRY

INQUIRY