Application Fields:

Widely used in content measurement of metal elements, such as in industries of metal smelting, casting, and processing, or in mechanical industries where element testing is a traditional item during research and development, production control, quality inspection, etc.

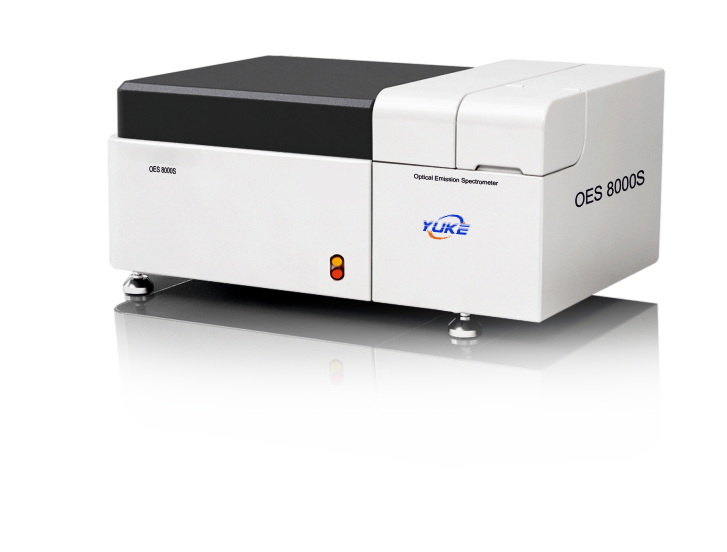

Product Features:

Full spectrum technology for convenient configuration of more matrices and elements by customers

The instrument requires no big laboratory space due to its small size.

All-weather working, with excellent stability and reliability

High test speed, with single test in less than 40 seconds

Easy to use and maintain, and low requirements for operators’ qualifications

Original factory program, which delivers accurate test data and has a complete alloy grades library;

Standard samples are provided for periodic calibration of instruments

The test process is safe and environmental-friendly, as chemical reagents are not used.

Advantages:

Full spectrum detection and testing of various metals and elements:

Based on the full spectrum testing technology of CMOS detector, the spectrum lines of elements in various metals are tested, which is convenient for multi-matrix and multi-element testing.

It is extremely convenient to configure and supplement the test matrix, channel, and analysis program, which is convenient for supplementing the test elements and analysis programs at the customer after delivery.

Core components provided by top international suppliers:

Spectral dispersion element-the grating is manufactured by Zeiss of Germany/JY of France, ensuring excellent spectral resolution

Spectral detector-CMOS detector is manufactured by Hamamatsu of Japan, ensuring sensitive and low-noise spectrum line detection

Light room constant temperature system:

The constant temperature cavity of the light room is equipped with a feedback heating device and a temperature insulation layer to effectively ensure the constant temperature in the light room.

Thereby suppressing the optical path drift caused by the slight change in the size of the mechanical parts under temperature changes. Except for special maintenance, tracing is generally not required for routine maintenance.

At the same time, the detector working in a constant temperature environment helps to stabilize the photoelectric conversion performance.

Rapid and simultaneous analysis of multiple elements in steel and non-ferrous metal materials

After placing the pre-treated sample on the sample table, OES8000s can present the test results in up to 40 seconds.

According to customer needs, the content of common elements in almost all steel and non-ferrous metal materials can be tested.

Professional test solutions:

With the accumulation of long-term testing technical services, Tianrui Instruments provides mature test solutions for users of steel and non-ferrous metal material analysis.

The test solution adopts an analysis procedure for the classification of material element content to meet various common test needs of users.

The analysis procedure is calibrated by the original factory using international and national standard samples, and is fitted and corrected by professional instrument software.

Users only need to use a small number of standardized samples configured by the original factory to complete daily maintenance, without purchasing a large number of standard samples for making analysis procedures.

Working conditions

Working temperature: 15-30℃

Relative humidity: ≤70%

Power supply: 220V, 50/60Hz, ground resistance <1Ω

Laboratory free of vibration, dust, strong electromagnetic interference, strong airflow, corrosive gas

Technical performance and indicators

1. Spectroscopic chamber design

Paschen-Runge structure, Rowland circle diameter 400mm

Wavelength range 140 – 680nm

Pixel resolution 10pm

Constant temperature 33℃±0.2℃

Special material casting to ensure small deformation of the optical chamber

Intermittent vacuum system to ensure that the vacuum pump running time is less than 5%

2. Concave grating

Line density 3600l/mm

Spectral line dispersion rate: 1.04 nm/mm

3. Detector

High-performance linear array CMOS

4. Analysis time

Varies depending on the type of sample, generally less than 40 seconds

5. Excitation light source

Fully digital plasma spark light source technology

High energy pre-combustion technology (HEPS)

Frequency 100-1000Hz

Current 1-80A

6. Excitation stage

3mm sample stage analysis gap

Jet electrode technology

Specially designed gas path system to ensure low argon consumption

7. Dimensions and weight

Height 450mm Length 900mm Width 600mm

120kg

8. Power

High power 1500W

Standby power 70W

Download

keyword search:Optical Emission Spectrometer

INQUIRY

INQUIRY