Summary

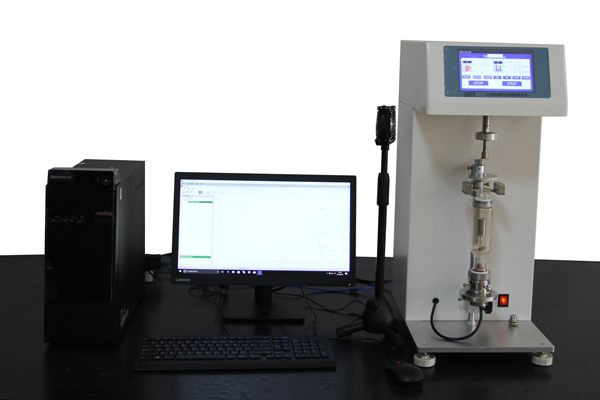

Comprehensive thermal analysis combines thermogravimetric analysis (TG) with differential thermal analysis (DTA) or differential scanning calorimetry (DSC), and thermogravimetric and differential thermal information can be obtained synchronously by using the same sample in the same measurement.

Thermogravimetric analysis (TG, TGA) is to observe the change of sample quality with temperature or time in the process of heating, constant temperature or cooling, with the purpose of studying the thermal stability and composition of materials. It is widely used in research and development, process optimization and quality control of plastics, rubber, coatings, pharmaceuticals, catalysts, inorganic materials, metal materials and composite materials.

Differential scanning calorimeter (DSC), as a classical thermal analysis method for controlling the thermal effect at programmed temperature, has been widely used in research and development, process optimization, quality control and failure analysis in various fields of materials and chemistry. Using DSC method, we can study the phase transition of inorganic materials, the melting and crystallization process of polymer materials, the polymorphism of drugs, the solid/liquid ratio of foods such as oils and fats, etc. It conforms to the national standards GB/T2951.42-2008, GB/T15065-2009, GB/T17391-1998 and GB/T19466.1-2009.

Technical characteristics

1. Adopt one millionth high-precision electronic balance with good stability and repeatability.

2. Industrial-grade widescreen touch structure, which displays rich information, including set temperature, sample temperature, oxygen flow rate, nitrogen flow rate, differential thermal signal and various switch states.

3, USB communication interface, strong versatility, reliable signal without interruption, support self-recovery connection function.

4. The furnace body is compact in structure, and the heating and cooling rate can be adjusted at will.

5. The digital gas mass flowmeter automatically switches two gas flows, with fast switching speed and short stabilization time.

6, standard samples, convenient for customers to correct the temperature coefficient.

7. Software adapts to computer screens with different resolutions; Support notebooks and desktops, and support operating systems such as WIN10 and WIN11.

8. Support the user's self-programming program to realize full automation of measurement steps. The software provides dozens of instructions, and users can flexibly combine the instructions according to their own measurement steps and save them. Complex operations are simplified to one-click operations.

Technical parameter

1、TG range: 0 ~ 1000 mg

2. TG resolution: 0.1ug

3. TG accuracy: ±2ug

4. DSC range: 0 ~ 200 MW

5. DSC accuracy: 2%

6. DSC resolution: 0.001mW

7. DSC resolution: 0.001mW

8. Temperature range: room temperature ~ 1000℃

9. Heating rate: 0.1 ~ 50℃/min

10. Temperature resolution: 0.01℃

11. Temperature accuracy: 1℃

12. Temperature repeatability: 1℃

13. Temperature control mode: heating, constant temperature, cooling and circulating temperature control (full program automatic control).

14. Curve scanning: heating scanning.

15. Atmosphere control: The gas mass flowmeter automatically switches between two gases.

16. Display mode: 24bit color, 7-inch LED touch screen display.

17. Data interface: USB standard interface with corresponding operating software.

18. Parameter standard: equipped with standard calibrator, with one-button calibration function, users can calibrate the temperature by themselves.

19. Working power supply: AC220V 50Hz/60Hz.

Application example

TG: thermal stability, decomposition process, adsorption and desorption, oxidation and reduction, quantitative analysis of components, effects of additives and fillers.

DSC: Measuring physical and chemical changes related to heat, such as glass transition temperature and melting point. Melting temperature, crystallization and crystallization heat, phase transition reaction heat, product thermal stability, curing/crosslinking, oxidation induction period, reaction kinetics, specific heat, etc.

After-sales description

1. The product is guaranteed for one year from the factory date (except for man-made failures).

2. The manufacturer provides users with lifelong technical services for products.

3. Software: free conversion between Chinese and English, free upgrade for life.

4. Home installation training

5. After-sales telephone number: 86 16601757347

Download

INQUIRY

INQUIRY