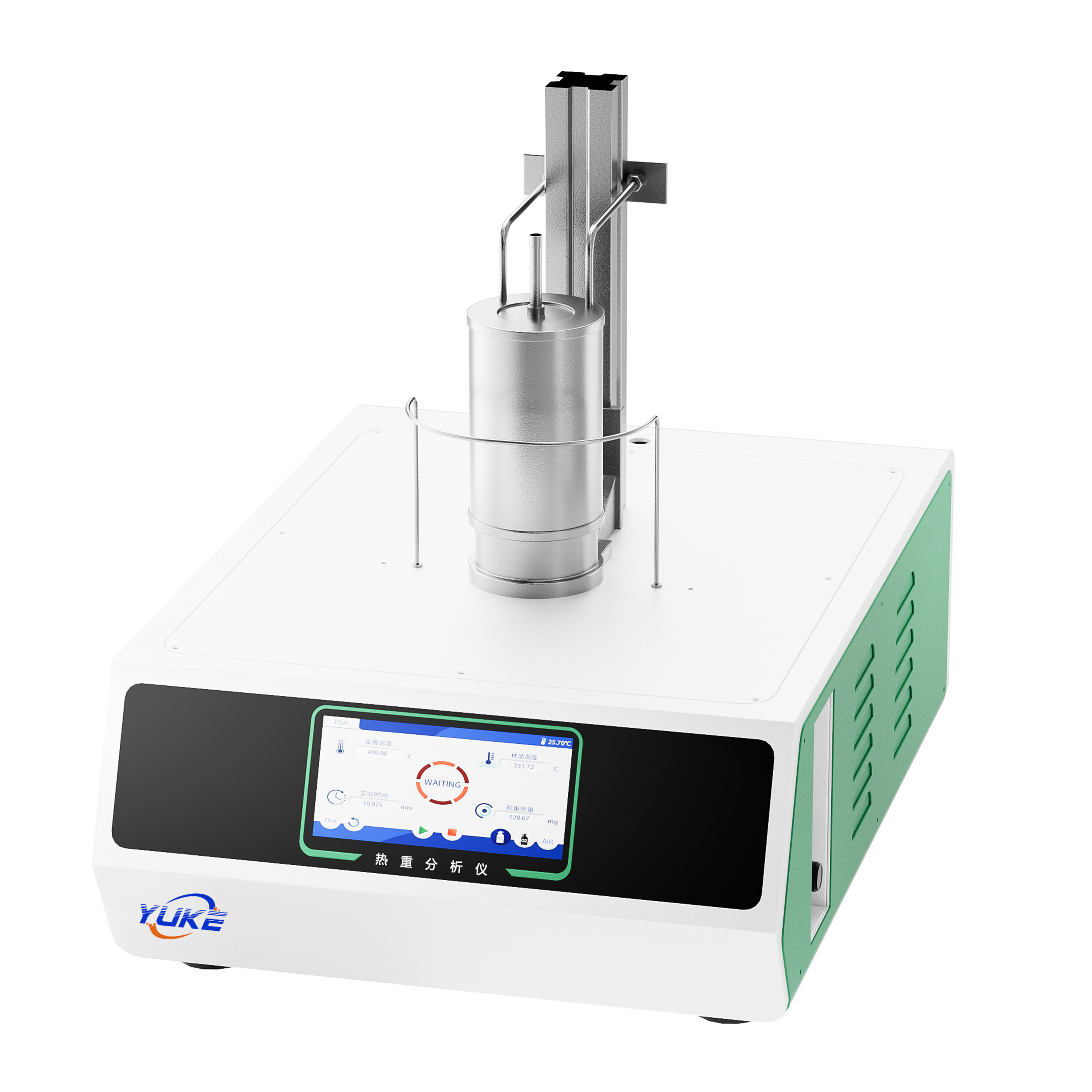

Instrument Introduction

Simultaneous Thermal Analysis combines Thermogravimetric Analysis TG with Differential Thermal Analysis DTA or Differential Scanning Calorimetry DSC into a single unit, where the same sample can be used in the same measurement to obtain simultaneous information of TG and DTA or DSC. Thermogravimetric analysis (TG, TGA) is to observe the change in mass of a sample with temperature or time during warming, constant temperature or cooling, with the aim of studying the thermal stability and composition of materials.It is widely used in research and development, process optimisation and quality control in various fields such as plastics, rubber, coatings, pharmaceuticals, catalysts, inorganic materials, metal materials and composites.Simultaneous Thermal Analysis combines Thermogravimetric Analysis TG with Differential Thermal Analysis DTA or Differential Scanning Calorimetry DSC into a single unit, where the same sample can be used in the same measurement to obtain simultaneous information of TG and DTA or DSC.

Instrument Usage

Measure and study the following properties of materials.

DSC: melting, crystallisation, phase transitions, reaction temperature and heat of reaction, heat of combustion, specific heat ......

TG: Thermal stability, decomposition, redox, adsorption and desorption, free water and water of crystallisation content, calculation of component ratios.

Main features

1、Built-in imported mass weighing balance, with internal calibration and temperature compensation function, the quality change can respond quickly, with better accuracy and repeatability;

2、The instrument built-in mass level guiding function, in the scale range, the sample position changes do not affect the quality of the results;

3、The internal balance chamber is equipped with a constant temperature water bath device to ensure the constant temperature of the balance chamber, which greatly improves the stability of weighing;

4、The instrument can do sample weight gain or weight loss type of experiments, such as sample adsorption and decomposition process;

5、Closed ceramic insulation furnace structure, greatly improving the signal sensitivity and resolution, can obtain a more stable baseline;

6、Modular design of the furnace body, more flexible mobility, maintenance is more convenient;

7、The furnace body is designed with a dual gas circuit internal blowing structure, can better ensure that the experimental process of airtight;

8、The furnace body is designed with internal capillary water circulation refrigeration structure, the device wrapped around the furnace body, for the furnace body cooling;

9、The furnace body can be reserved according to customer demand for experimental exhaust gas treatment interface, can be carried out experimental exhaust gas secondary analysis;

10、The sensor bracket is designed using imported materials, equipped with K-type or E-type sensors can be arbitrarily switched through the software, different test occasions can flexibly select the type of sensor, especially suitable for phase change of polymer materials, glass transition class experiments;

11、The sampling frequency of the sensor signal 0.05 ~ 10Hz can be set, the experimental method is more flexible, more controllable data;

12、Dual temperature sensor design concept, can be tested at the same time the internal temperature of the furnace and the sample temperature;

13、The full temperature control system using optimised dynamic PID algorithm, which greatly circumvents the shortcomings of the traditional PID algorithm, and improves the robustness of dual-mode temperature control;

14、With FTC and STC two experimental modes can be set, the temperature control is more friendly and flexible, can meet the needs of different experiments in different application scenarios, the temperature control of the experimental process is more accurate, the analysis of the sensor signal is more efficient, precise control of the experimental results;

15、12-order programme temperature control settings, so that the experimental method is more diverse, and the device has a cycle scanning function, the number of cycle scanning can be set up to 9999 times, the data is automatically saved;

16、the equipment system of the lower and upper computer at the same time with multi-point temperature correction function to meet the needs of different experimental occasions, improve the accuracy of temperature testing;

17、The instrument is equipped with imported high-frequency kernel control processor, computing and processing speed faster, more efficient control;

18、Mutually independent atmosphere control, can be intelligently set up through the software, the instrument automatically switches the gas system, the experiment is more efficient;

19、The equipment system can do heating, cooling and isothermal related classes of materials experiments;

20、The use of 7-inch 24bit colour full-colour LCD touch screen, real-time display of the status of the instrument and data;

21、The instrument adopts USB two-way communication, software intelligent design, with the deduction of the baseline function, automatic issuance of the experimental report, the experimental process of automatic drawing, intelligent implementation of a variety of data processing, such as the glass transition temperature, oxidation-induced period, the melting point of the material and crystallisation and so on.

Technical parameters

1 | Temperature Range | Room temperature~1250℃ |

2 | Temperature resolution | 0.01℃ |

3 | Temperature fluctuation | ±0.01℃ |

4 | Temperature rise rate | 0.1~100℃/min |

5 | Balance Measuring Range | 0.01mg-5g |

6 | Mass Resolution | 0.01mg |

7 | DSC Range | 0~±2000 mW |

8 | DSC Sensitivity | 0.001 mW |

9 | Constant Temperature Time | 0~500min (arbitrary setting) |

10 | Cooling Time | 30min (1000℃...100℃) |

11 | Timing Frequency | 16.6Hz |

12 | Sampling Rate | 0.05~10Hz can be set programmatically |

13 | Sensor Type | K-type, E-type can be arbitrarily switched (K-type standard, E-type optional) |

14 | Experiment Mode | FTC, STC mode can be set arbitrarily |

15 | Experiment type | Weight loss, weight gain (adsorption) |

16 | Programmed temperature control | Flexible setting of 12 stages of temperature control |

17 | Temperature control mode | Temperature rise, constant temperature, temperature fall |

18 | Number of scans | Cycle scanning times can be set up to 9999 times, and the data is automatically saved. |

19 | Calibration | The lower and upper computer have multi-point temperature correction function at the same time. |

20 | Display mode | 24bit colour 7 inch LCD touch screen display. |

21 | Atmosphere control | The two atmospheres can be set freely, and the instrument switches automatically. |

22 | Parameter Standard | Equipped with standard substances, the user can self-correct the temperature |

23 | Power supply | AC220V/50Hz(AC110V can be customised) |

Download

keyword search:STA Synchronous Thermal Analyzer

INQUIRY

INQUIRY