Introduction

Thermogravimetric analysis (TG, TGA) is to observe the mass of the sample with temperature or time during the heating, constant temperature or cooling process, the purpose is to study the thermal stability and composition of the material. Widely used in plastics, rubber, coatings, drugs, catalysts, inorganic materials, metal materials and composite materials and other fields of research and development, process optimization and quality monitoring.

Instrument use

The following characteristics of the materials were measured and studied: thermal stability, decomposition process, adsorption and desorption, oxidation and reduction, quantitative analysis of composition, influence of additives and fillers, water and volatiles, reaction kinetics, etc.

Main features

1、Built-in import quality weighing balance, with internal calibration and temperature compensation function, quality changes can respond quickly, with better accuracy and repeatability;

2、The instrument built-in quality level guidance function, in the range of the scale plate, the change of sample position does not affect the quality results;

3、The internal balance room is equipped with constant temperature water bath device to ensure the constant temperature of the balance room, greatly improving the stability of weighing;

4、The instrument can do sample weight gain or weightlessness experiments, such as sample adsorption and decomposition process;

5、Closed ceramic thermal insulation furnace body structure, greatly improves the signal sensitivity and resolution, can obtain a more stable baseline;

6、Modular design of the furnace body, more flexible mobility, more convenient maintenance;

7、The internal design of the furnace body has a double air path purge structure, which can better ensure the air tightness of the experimental process;

8、The furnace body interior design has a capillary water circulation refrigeration structure, which packages the furnace body for the cooling of the furnace body;

9、The furnace body can reserve the experimental tail gas treatment interface according to the customer demand, which can carry out the secondary analysis of the experimental tail gas;

10、The sensor support is designed with imported materials, more corrosion resistance, oxidation resistance and high sensor sensitivity.

11、The sampling frequency of the sensor signal can be set at 0.05~10Hz, and the experimental method is more flexible and the data is more controllable;

12、Dual temperature sensor design concept can test the internal temperature and sample temperature at the same time;

13、The full temperature control system adopts the optimized dynamic PID algorithm, which greatly avoids the disadvantages of the traditional PID algorithm and improves the robustness of the dual-mode temperature control;

14、With FTC and STC two experimental modes can be set, the temperature control is more friendly and flexible, can meet the needs of different application scenarios and different experiments, the experimental process temperature control is more accurate, the analysis of the sensor signal is more efficient, accurate control of the experimental effect;

15、The 12th order program temperature control setting makes the experimental method more diversified, and the equipment has the function of cycle scanning, the cycle scanning times can be set up to 9999 times, the data is automatically saved;

16、The lower computer and the upper computer of the equipment system simultaneously have the multi-point temperature correction function, which can meet the needs of different experimental occasions and improve the accuracy of the temperature test;

17、The instrument is equipped with imported high frequency core control processor, the processing speed is faster, more efficient control;

18、Independent atmosphere control can be set by software intelligence, the instrument automatically switch the gas system, the experimental efficiency is higher;

19、The equipment system can do heating, cooling and isothermal related materials experiments;

20、7-inch 24bit color LCD touch screen to display the status and data of the instrument in real time.

Technical parameter

1 | Temperature range | RT ~ 1,250℃ |

2 | Temperature resolution | 0.01℃ |

3 | Temperature fluctuation | ±0.01℃ |

4 | Heating rate | 0.1~100℃/min |

5 | Scale measurement range | 0.01mg-5g |

6 | Quality resolution | 0.01mg |

7 | The constant temperature time | 0~500min (arbitrary set) |

8 | Cooling-off period | 30min(1000℃…100℃) |

9 | Toggle rate | 16.6Hz |

10 | Sampling rate | 0.05~10Hz can program setting |

11 | Experimental mode | FTC, STC mode are arbitrarily set |

12 | Type of experiment | Weight loss and weight gain (adsorption) |

13 | Procedure temperature control | The whole stage is 12 order temperature control flexible setting |

14 | Temperature control mode | Heat up, constant temperature, cooling |

15 | Cycle index | The number of cycle scans can be set up to 9999, and the data is automatically saved |

16 | Instrument calibration | Both the lower computer and the upper computer have a multi-point temperature correction function |

17 | Display mode | 24bit color 7-inch LCD touchscreen display |

18 | Atmosphere control | Two atmosphere can be set freely, the instrument will automatically switch |

19 | Parameter standard | Equipped with the standard material, the user can correct the temperature by himself |

20 | Source | AC220V / 50Hz (customizable AC110V) |

Packing List

No. | Items | Quantity | Remarks |

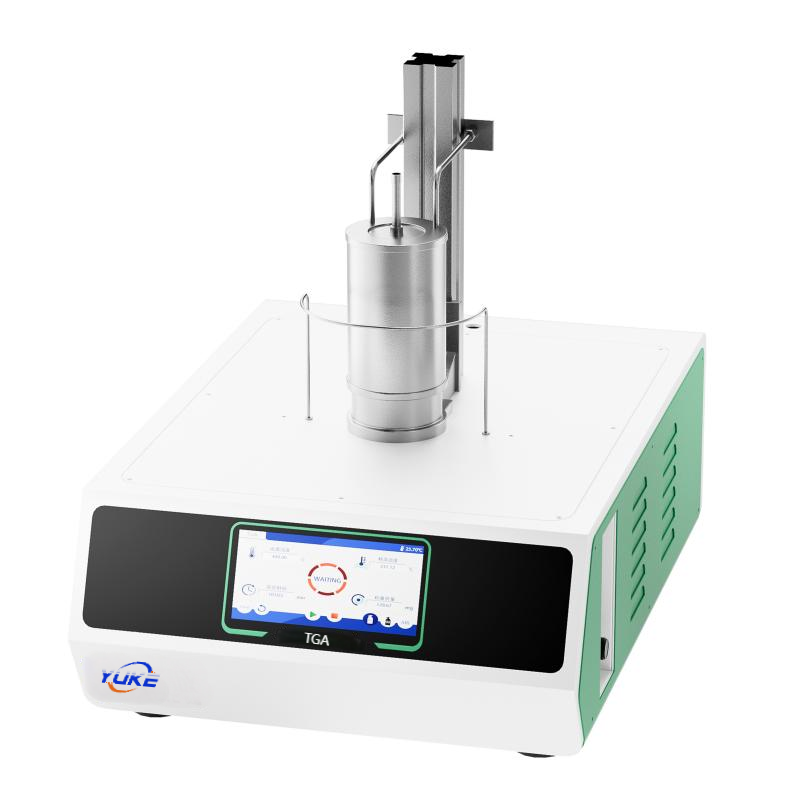

1 | The TGA-712S host | 1 |

|

2 | Power line | 1 |

|

3 | Experimental software U disk | 1 |

|

4 | Data wire | 1 |

|

5 | Crucible | 100 |

|

6 | Water pump | 2 |

|

7 | Pump adapter | 2 |

|

8 | Multi-function wrench | 1 |

|

9 | Tweezers | 1 |

|

10 | Fuse | 5 |

|

11 | PU air tube | 2 |

|

12 | Silicone hose | 4 |

|

13 | Sample spoon | 1 |

|

14 | Qualification certificate, warranty card, instruction manual | 1 |

|

Note: Your required configuration: computer, nitrogen bottles, oxygen bottles and supporting pressure relief meters

Download

keyword search:Thermogravimetric Analyzer

INQUIRY

INQUIRY